UME

Loughborough University

2019

UME is a user testing headset that allows creative professionals to gather valuable data-driven insights on emotional response.

Intuitive design, automated data analysis, and a streamlined user experience increase the accessibility of technology previously exclusive to research scientists.

USING THE TECHNOLOGY

EEG technology is traditionally used to diagnose brain traumas and provides data on regional brain activity. This data can also be used to evaluate emotional dynamics, such as stress, fatigue, excitement and relaxation.

It is a complex, time-consuming process that is overlooked for user testing purposes due to the expertise required to set up, complex data analysis, and the uncomfortable participant experience.

UME improves both the physical and digital experience of using the technology. An easy to adjust, lightweight and intuitive headset is supported by automated data analysis and refined instructions. By streamlining the technology, UME allows user testing professionals to gather valuable, detailed data-driven insights without expensive expert support.

INDUSTRIAL DESIGN

The chosen design direction aimed to reduce the anxiety associated with traditional medical EEG headsets. This is a significant issue in using the technology in user research applications as anxiety and stress levels directly influence data readings.

MECHANICAL DEVELOPMENT

A modular 3D printed prototype was developed to test conceptual mechanical interaction features, for example the twist to adjust EEG sensors (right).

The prototype was designed for different parts and ideas to be interchangable. The white parts were printed out of TPU to simulate different ranges of elastic movement.

It was noted amongst participants that using clockwise twist to adjust features around the entire head was confusing. The rotational axis was therefore mirrored across the central axis of the headset.

SKETCH EXPLORATION

Once the mechanical prototypes had been tested, insights and solutions to problems were explored through sketching. Mechanical solutions and visual design were explored simultaneously to investigate how they could best be visually executed.

CONCEPT REFINEMENT

Before developing a detailed 3D CAD model the final visual design was defined using photoshop rendering.

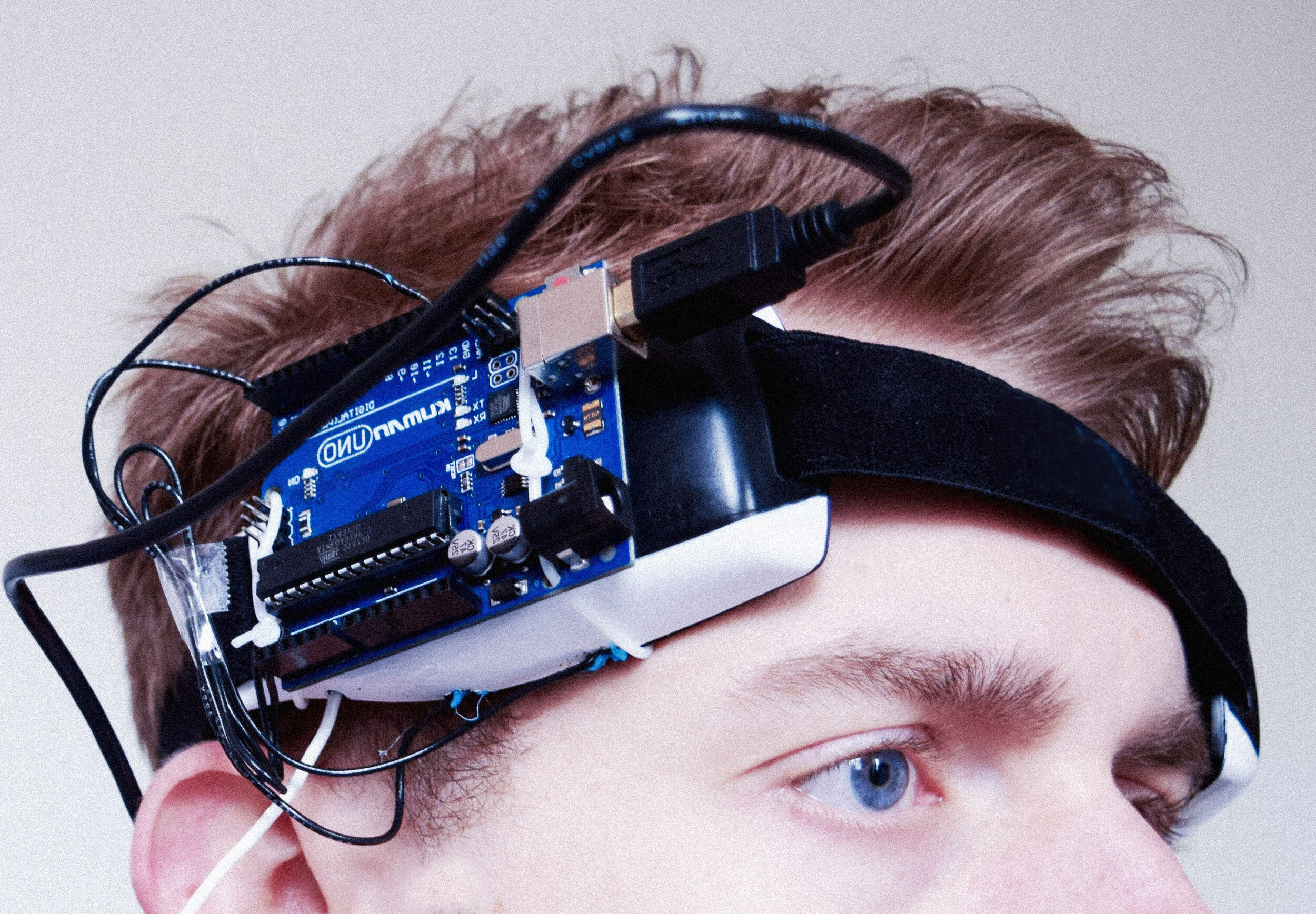

FUNCTIONAL ELECTRONIC PROTOTYPE

A functional prototype was created by hacking an EEG toy, integrating an Arduino electronics kit and then utilising open-source data presentation code.

The most important insight from this prototype was how different calibration was needed for each participant. Location on the head, skin moisture, and movement were much more significant variables than expected.

The prototype was also used to refine data presentation and automated insight gathering.

Through this prototype testing, an additional function was coded in Arduino to shine an LED only visible to the host of the test to inform them connection was interrupted.

DESIGN FOR MANUFACTURE

Preliminary cost estimation lead to drastic changes to the pre-production design. Mirrored components and tesselating fabric templates were used to reduce the cost of manufacture by 35%. This placed UME within the competitive range of competitors when manufactured in quantities of 500+.